Bespoke blade fabrication

Bespoke blade fabrication

Bespoke blade fabrication

Bespoke Blade Fabrication: Crafting Tailored Precision Solutions

Introduction: Bespoke blade fabrication represents the pinnacle of precision engineering, offering tailored solutions to meet the unique needs of industries worldwide. In this comprehensive exploration, we delve into the world of bespoke blade fabrication, uncovering the intricacies of the fabrication process, innovative technologies utilized, and the diverse applications where bespoke blades excel.

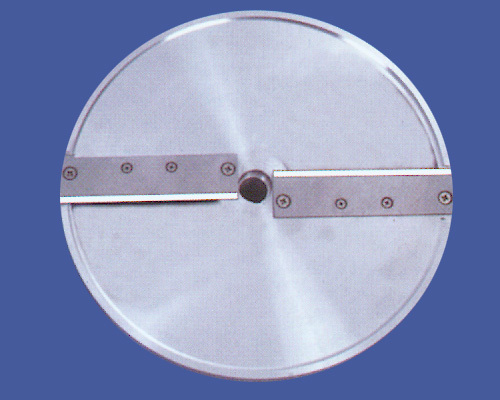

Section 1: Understanding Bespoke Blade Fabrication Bespoke blade fabrication goes beyond conventional manufacturing, focusing on the creation of custom blades tailored to specific requirements. This section provides an overview of bespoke blade fabrication, highlighting the key elements involved in the process and the importance of precision in meeting customer needs.

Section 2: The Art and Science of Blade Fabrication Bespoke blade fabrication is a blend of art and science, where skilled craftsmen and engineers work together to create precision-engineered solutions. This section explores the factors considered in blade fabrication, including material selection, design optimization, and manufacturing techniques. Advanced modeling and simulation tools enable fabricators to visualize and analyze blade performance, ensuring optimal results.

Section 3: Materials Selection and Optimization Material selection is critical in bespoke blade fabrication, with a wide range of alloys, ceramics, and composites available to meet specific performance requirements. This section examines the materials used in bespoke blade fabrication and the factors considered when selecting and optimizing materials for each application. Advanced manufacturing techniques such as forging, casting, and CNC machining enable fabricators to shape and refine blade materials with precision and consistency.

Section 4: Precision Manufacturing Processes Precision manufacturing processes are essential in bespoke blade fabrication to ensure the highest level of accuracy and consistency. This section explores the various fabrication techniques employed, including cutting, grinding, and finishing, each tailored to the specific requirements of the blade design and material properties. Quality control measures such as dimensional inspection and performance testing are implemented throughout the fabrication process to ensure that each blade meets the highest standards of quality and reliability.

Section 5: Applications Across Industries Bespoke blades find applications across a wide range of industries, each with its own unique set of challenges and requirements. This section highlights some of the key industries that rely on bespoke blades, including aerospace, automotive, medical, and manufacturing. From precision cutting to surgical procedures, bespoke blades play a critical role in enhancing efficiency, quality, and safety across diverse applications.

Section 6: Innovations Driving the Future The field of bespoke blade fabrication is constantly evolving, driven by innovations in materials science, manufacturing technologies, and design optimization. This section explores some of the latest advancements in bespoke blade fabrication, including the use of additive manufacturing, nanotechnology, and artificial intelligence to push the boundaries of what is possible. These innovations are reshaping the landscape of bespoke blade fabrication, opening new possibilities for efficiency, performance, and sustainability.

Section 7: Sustainability and Environmental Responsibility In an era of increasing environmental awareness, sustainability and environmental responsibility are becoming increasingly important considerations in bespoke blade fabrication. This section examines some of the sustainable practices and initiatives being adopted by fabricators to minimize environmental impact, reduce waste, and conserve natural resources. From eco-friendly materials to energy-efficient manufacturing processes, the industry is taking proactive steps to ensure a more sustainable future.

Section 8: Global Market Dynamics The global market for bespoke blade fabrication is characterized by steady growth, driven by increasing demand from key industries such as aerospace, medical, and manufacturing. This section explores some of the key market trends and dynamics shaping the industry, including emerging opportunities in regions such as Asia-Pacific, Latin America, and the Middle East. Strategic partnerships, mergers, and acquisitions are reshaping the competitive landscape as companies seek to expand their market presence and gain a competitive edge.

Section 9: Conclusion and Outlook In conclusion, bespoke blade fabrication represents the epitome of precision engineering and innovation, offering tailored solutions to meet the diverse needs of industries worldwide. As we look ahead, the future of bespoke blade fabrication is bright, fueled by a relentless pursuit of excellence and a commitment to pushing the boundaries of what is possible. Let us continue to embrace innovation, collaboration, and sustainability as we strive to create a future where bespoke blades play a central role in driving efficiency, quality, and progress across a wide range of industries.