Blade customization

Blade customization

Blade customization

Title: Blade Customization: Tailoring Precision Tools to Perfection

Introduction: Blade customization stands as a testament to the artistry and engineering prowess of modern manufacturing. In this extensive exploration, we embark on a journey into the heart of blade customization, unraveling the intricate processes, innovative technologies, and diverse applications that define this dynamic sector.

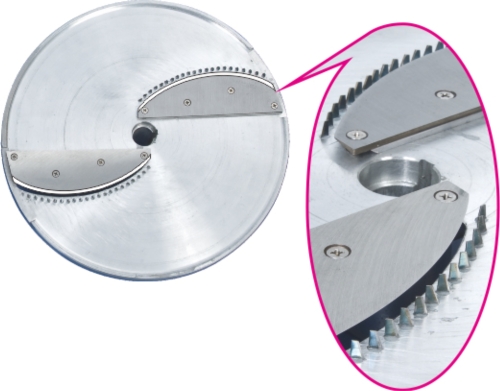

Section 1: The Essence of Blade Customization Blade customization embodies the essence of tailoring precision tools to meet specific needs and preferences. It encompasses a spectrum of design options, material choices, and performance enhancements tailored to individual requirements. From the curvature of a cutting edge to the composition of blade alloys, customization offers limitless possibilities for optimization and innovation.

Section 2: Designing the Perfect Blade At the core of blade customization lies the art of design, where engineers and artisans collaborate to bring concepts to life. This phase involves a deep understanding of cutting dynamics, material properties, and application requirements. CAD software and simulation tools enable designers to visualize and iterate designs with unparalleled precision, ensuring optimal performance and functionality.

Section 3: Materials and Manufacturing Processes Blade customization opens doors to a wide array of materials and manufacturing processes, each offering unique advantages and characteristics. High-speed steel, carbide, ceramic, and advanced alloys are among the materials of choice, each tailored to specific applications and performance requirements. Manufacturing processes such as CNC machining, laser cutting, and precision grinding enable the transformation of raw materials into precision-crafted blades.

Section 4: Tailored Solutions for Diverse Industries Blade customization finds applications across a myriad of industries, each with unique demands and challenges. In aerospace, custom blades enable high-precision cutting of advanced composite materials for aircraft structures. In healthcare, they facilitate delicate surgeries with minimal tissue damage. From automotive engineering to food processing, customized blades play a pivotal role in enhancing efficiency, quality, and safety.

Section 5: Precision Engineering in Action Behind every custom blade lies a testament to precision engineering and meticulous craftsmanship. Manufacturers leverage advanced metrology tools and quality control protocols to validate dimensional accuracy, surface finish, and performance characteristics. From initial design to final inspection, every step in the manufacturing process is scrutinized to ensure uncompromising quality and reliability.

Section 6: Innovations Driving the Future The landscape of blade customization is shaped by continuous innovation and technological advancements. Additive manufacturing, machine learning algorithms, and nanotechnology are among the emerging trends revolutionizing the way blades are conceived, designed, and produced. These innovations promise to unlock new possibilities for performance, durability, and sustainability in the years to come.

Section 7: Customization Beyond the Blade Blade customization extends beyond the physical characteristics of the blade itself, encompassing ancillary services such as blade sharpening, coating, and refurbishment. Manufacturers offer tailored solutions to address evolving needs and challenges, partnering closely with clients to deliver comprehensive blade management programs and aftermarket support services.

Section 8: Sustainability and Environmental Responsibility In an era of heightened environmental consciousness, blade customization is embracing sustainable practices and eco-friendly materials. Manufacturers are investing in recycling initiatives, energy-efficient manufacturing processes, and green packaging solutions to minimize environmental impact and promote long-term sustainability.

Section 9: Global Market Dynamics The global market for blade customization is characterized by robust growth, driven by increasing demand from key end-user industries such as manufacturing, aerospace, and healthcare. Market players are expanding their geographic footprint and diversifying their product portfolios to capitalize on emerging opportunities in regions such as Asia-Pacific and Latin America.

Section 10: Conclusion and Outlook In conclusion, blade customization represents the pinnacle of precision engineering and creative innovation, offering tailored solutions to meet the evolving needs of modern industries. As we look ahead, the future of blade customization is bright, fueled by a relentless pursuit of excellence and a commitment to pushing the boundaries of what is possible. Let us continue to embrace customization as a catalyst for progress, shaping a future where precision knows no limits.