Blade design services

Blade design services

Blade design services

Blade Design Services: Crafting Custom Solutions for Precision Engineering

Introduction: Blade design services are essential for industries that demand precision tools tailored to their specific needs. In this comprehensive exploration, we delve into the realm of blade design services, uncovering the intricacies of the design process, innovative technologies utilized, and the wide array of applications where custom blades excel.

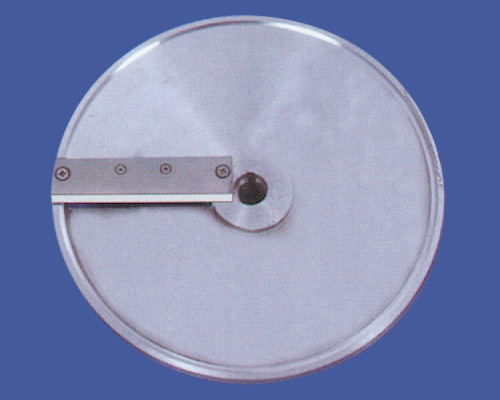

Section 1: Understanding Blade Design Services Blade design services encompass a range of activities, from initial concept development to final production. These services are offered by specialized firms with expertise in engineering, materials science, and manufacturing. Clients turn to blade design services when off-the-shelf solutions fail to meet their unique requirements, seeking tailored designs that optimize performance and efficiency.

Section 2: The Art and Science of Blade Design Blade design is a blend of art and science, where engineers and designers collaborate to create solutions that balance functionality, durability, and performance. This section explores the factors considered in blade design, including material selection, geometric considerations, and aerodynamics. Advanced modeling and simulation tools enable designers to visualize and analyze blade performance under various conditions, refining designs to achieve optimal results.

Section 3: Tailoring Blades to Specific Applications Blade design services cater to a diverse range of industries, each with its own set of challenges and requirements. From aerospace to medical devices, custom blades play a critical role in enhancing efficiency and precision. This section highlights some of the key applications of blade design services, including turbine blades for power generation, cutting tools for manufacturing, and surgical instruments for medical procedures.

Section 4: Leveraging Advanced Technologies Blade design services leverage advanced technologies to push the boundaries of what is possible. Additive manufacturing techniques, such as 3D printing, enable the creation of complex blade geometries with unprecedented precision. Computational fluid dynamics (CFD) simulations optimize blade aerodynamics, minimizing drag and maximizing efficiency. These technologies empower designers to explore innovative solutions that were once thought impossible.

Section 5: Collaboration and Customization Successful blade design services rely on close collaboration between clients and designers. This section explores the collaborative process involved in blade design, from initial consultations to prototype testing. Client input is essential in understanding the specific requirements and constraints of each project, ensuring that the final design meets or exceeds expectations.

Section 6: Quality Assurance and Testing Quality assurance is paramount in blade design services, with rigorous testing protocols employed to validate performance and reliability. This section examines the testing procedures used to evaluate blade designs, including mechanical testing, fatigue analysis, and field trials. By subjecting blades to real-world conditions, designers can identify potential weaknesses and make necessary adjustments to improve performance.

Section 7: Sustainability and Environmental Responsibility In an increasingly eco-conscious world, sustainability is a key consideration in blade design services. This section explores sustainable practices in blade design, such as using recyclable materials, minimizing waste during manufacturing, and optimizing blade designs for energy efficiency. By prioritizing sustainability, blade design services can minimize environmental impact while delivering high-quality solutions to clients.

Section 8: Global Market Dynamics The global market for blade design services is driven by demand from industries such as aerospace, automotive, and renewable energy. This section examines market trends and dynamics, including emerging opportunities in regions such as Asia-Pacific and Latin America. Strategic partnerships and collaborations are reshaping the competitive landscape as firms seek to expand their market presence and gain a competitive edge.

Section 9: Conclusion and Outlook In conclusion, blade design services play a vital role in meeting the evolving needs of industries worldwide. As technology continues to advance and market demands evolve, the future of blade design services is bright. By embracing innovation, collaboration, and sustainability, blade design services can continue to push the boundaries of what is possible, delivering custom solutions that drive efficiency, precision, and progress across a wide range of industries.