Custom blade manufacturing

Custom Blade Manufacturing

Custom Blade Manufacturing

Custom Blade Manufacturing: Crafting Precision Tools for Diverse Industries

Introduction: Custom blade manufacturing stands at the forefront of precision engineering, offering tailored solutions to industries spanning from aerospace to healthcare. In this comprehensive exploration, we delve into the intricate world of custom blade production, uncovering the meticulous processes and innovative techniques that drive this dynamic sector forward.

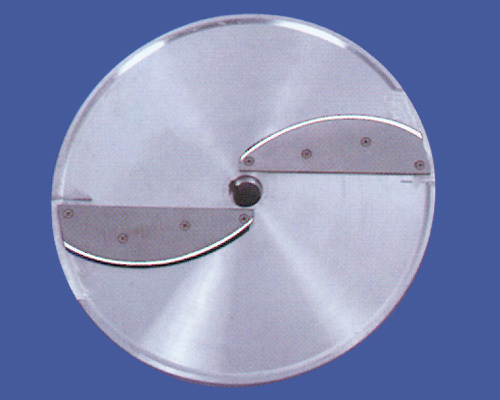

Section 1: The Art of Custom Blade Design Custom blade manufacturing begins with the art of design, where skilled engineers and craftsmen translate client specifications into tangible blueprints. This phase involves a meticulous understanding of material properties, cutting dynamics, and application requirements. From the curvature of a surgical scalpel to the intricacies of a turbine blade, each design iteration is a testament to precision and innovation.

Section 2: Materials and Manufacturing Processes The choice of materials is paramount in custom blade manufacturing, with options ranging from high-speed steel to advanced ceramics. Manufacturers leverage cutting-edge technologies such as CNC machining, laser cutting, and EDM wire erosion to transform raw materials into precision-crafted blades. Surface treatments and coatings are applied to enhance durability, corrosion resistance, and performance in challenging environments.

Section 3: Tailored Solutions for Diverse Applications Custom blades find applications across a myriad of industries, each with unique demands and challenges. In aerospace, they enable high-precision cutting of composite materials for aircraft structures. In medical devices, they facilitate intricate surgeries with minimal tissue damage. From food processing to automotive engineering, custom blades play a pivotal role in optimizing efficiency and quality.

Section 4: Precision Engineering in Action Behind every custom blade lies a testament to precision engineering and relentless quality control. Manufacturers employ advanced metrology tools such as coordinate measuring machines (CMMs) and optical scanners to validate dimensional accuracy and geometric tolerances. Rigorous testing protocols ensure that each blade meets stringent performance standards before reaching the hands of the end-user.

Section 5: Collaboration and Innovation The landscape of custom blade manufacturing is characterized by collaboration and innovation, with manufacturers partnering closely with clients to address evolving needs and challenges. From rapid prototyping to continuous improvement initiatives, the industry thrives on a culture of innovation, driving the development of next-generation blade technologies.

Section 6: Sustainability and Environmental Responsibility In an era of heightened environmental consciousness, custom blade manufacturers are embracing sustainable practices and eco-friendly materials. Recycling initiatives, energy-efficient manufacturing processes, and green packaging solutions are just a few examples of industry efforts to minimize environmental impact and foster long-term sustainability.

Conclusion: Custom blade manufacturing epitomizes the marriage of art and science, blending precision engineering with creative innovation to deliver tailored solutions to a diverse array of industries. As technology continues to evolve and market demands evolve, the industry stands poised to lead the charge towards a future defined by precision, quality, and sustainability.

Section 7: Addressing Industry Challenges Despite the advancements in custom blade manufacturing, the industry faces its share of challenges. From cost pressures to regulatory compliance, manufacturers must navigate a complex landscape to remain competitive. Rising raw material costs, global supply chain disruptions, and geopolitical uncertainties underscore the need for agility and resilience in the face of adversity.

Section 8: Advancements in Blade Technology The evolution of blade technology is a testament to human ingenuity and innovation. From nanotechnology-enhanced cutting edges to self-sharpening blade coatings, manufacturers are constantly pushing the boundaries of what is possible. Emerging trends such as additive manufacturing and AI-driven design optimization promise to revolutionize the way blades are conceived, designed, and produced.

Section 9: The Future of Custom Blade Manufacturing As we gaze into the future, the prospects for custom blade manufacturing are both exciting and promising. The rise of Industry 4.0 technologies, including IoT-enabled sensors and predictive maintenance algorithms, heralds a new era of smart manufacturing where blades are not just tools, but intelligent assets capable of self-monitoring and self-optimization.

Section 10: Global Market Dynamics The global custom blade manufacturing market is poised for steady growth, driven by increasing demand from key end-user industries such as automotive, aerospace, and healthcare. Market players are expanding their geographic footprint and diversifying their product portfolios to capitalize on emerging opportunities in regions such as Asia-Pacific and Latin America.

Section 11: Conclusion and Call to Action In conclusion, custom blade manufacturing represents a convergence of craftsmanship, technology, and innovation, delivering precision-engineered solutions to meet the evolving needs of modern industries. As we embark on this journey of discovery and exploration, let us continue to push the boundaries of what is possible, harnessing the power of collaboration, creativity, and ingenuity to shape a future where precision knows no bounds.