刀片

刀片是指用於切割、削除或修整材料的薄片狀切割工具,刀片是指用於切割、削除或修整材料的薄片狀切割工具,通常由金屬材料製成,例如不鏽鋼、高碳鋼、碳化鎢等。刀片的形狀和尺寸可以根據不同的應用需求進行設計和製造,例如直刀、弧刀、曲刀、鋸齒刀等。

刀片是指用於切割、削除或修整材料的薄片狀切割工具,刀片是指用於切割、削除或修整材料的薄片狀切割工具,通常由金屬材料製成,例如不鏽鋼、高碳鋼、碳化鎢等。刀片的形狀和尺寸可以根據不同的應用需求進行設計和製造,例如直刀、弧刀、曲刀、鋸齒刀等。

刀片通常用於各種切割和加工工作,例如食品加工、紡織、醫療器械、製造業等。不同的應用場合需要不同種類的刀片,例如食品加工需要使用不鏽鋼材質的刀片,以避免產生有害物質,紡織業需要使用碳化鎢刀片等。

刀片的選擇和使用需要注意以下幾點:

適當的刀片材質:不同應用場合需要使用不同材質的刀片,需要根據具體情況進行選擇。

正確的刀片尺寸和形狀:刀片的尺寸和形狀需要根據切割材料的特性和要求進行設計和選擇。

安全使用:在使用刀片時需要注意安全,以避免因刀片銳利而造成的傷害。

定期保養和更換:刀片需要定期進行保養和更換,以確保其良好的使用狀態和效果。

總的來說,刀片是一種非常實用和重要的切割工具,能夠應用於各種不同的工業領域。在使用刀片時需要注意安全和保養,以確保其良好的使用效果和使用壽命。

特殊用途刀片是指專門用於特定工業或應用領域的刀片。這些刀片通常需要根據不同的應用場合進行設計和製造,以適應不同的切割和加工要求。

以下是幾種常見的特殊用途刀片:

醫療器械刀片:用於手術、割傷縫合等醫療領域,需要有極高的精度和銳利度。

電子零件刀片:用於切割、修整和加工微小電子零件,需要有非常高的精度和靈活性。

塑膠刀片:用於切割、加工和修整各種塑膠制品,需要選擇適合的材料和設計。

紙張刀片:用於紙張加工、印刷等工藝中,需要有良好的切割效果和穩定性。

食品刀片:用於食品加工和處理,需要使用無毒、不鏽鋼等材料,以確保食品的安全和衛生。

特殊用途刀片的設計和製造需要專業的設計團隊和生產技術,以確保其符合應用要求和標準。在使用特殊用途刀片時需要注意安全和保養,定期進行維護和更換,以確保其良好的使用效果和使用壽命。

總的來說,特殊用途刀片是各種工業和應用領域中不可或缺的切割工具,能夠應用於各種不同的切割和加工要求。根據不同的應用場合和要求,需要選擇適合的特殊用途刀片,以確保工作效率和品質。

食品加工刀片是專門設計用於食品處理和加工的刀片。這些刀片具有特殊的特點和設計,以確保食品安全和衛生,並能夠有效地處理各種不同類型的食材。以下是一些常見的食品加工刀片類型和特點:

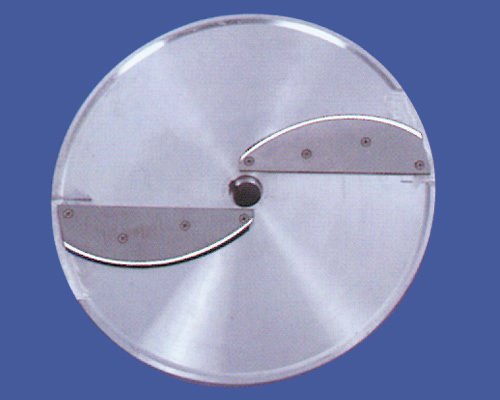

切片刀片: 這些刀片通常用於將肉類、蔬菜、奶製品等食材切成薄片或薄片狀,例如切生肉、切薯片等。

切丁刀片: 專門用於切成小丁狀的食材,如蔬菜、水果、肉塊等。這些刀片通常具有特殊的格柵刃,以實現均勻的切割。

剝皮刀片: 用於去除水果、蔬菜或其他食材的外皮。這些刀片通常具有較平滑的刃邊,以確保剝皮時不損害食材。

魚刀片: 這些刀片專門用於處理魚類,包括去鱗、剖魚、切魚肉等工作。它們通常具有特殊的刃形狀,以適應魚類的形狀和結構。

擠壓刀片: 用於將食材擠壓成特定形狀,例如製作餅乾、麵麻花、餡餅等。

磨刀片: 這些刀片用於將食材磨成蓉狀或粉末,例如芝麻醬、香料等。

釀造刀片: 用於製作壽司、切割壽司或其他食物加工需要的特殊刀片。

食品加工刀片通常由不鏽鋼或其他耐腐蝕材料製成,以確保食品不受污染。此外,它們需要經常保持清潔和消毒,以確保食品加工過程中的安全性和衛生標準。選擇適合的刀片類型取決於食品加工工藝和所需的切割或處理方式。食品業常遵循嚴格的食品安全法規,以確保生產的食品是安全的。 食品加工刀片是用於食品機械的特殊刀具,通常具有特殊的設計和特點,以滿足食品加工工業的需求。這些刀片可以用於切割、切片、切丁、剝皮、擠壓、磨碎等多種不同的食品處理任務。以下是一些常見的食品加工刀片類型:

食品加工刀片是專門設計用於食品處理和加工的刀片。這些刀片具有特殊的特點和設計,以確保食品安全和衛生,並能夠有效地處理各種不同類型的食材。以下是一些常見的食品加工刀片類型和特點:

切片刀片: 這些刀片通常用於將肉類、蔬菜、奶製品等食材切成薄片或薄片狀,例如切生肉、切薯片等。

切丁刀片: 專門用於切成小丁狀的食材,如蔬菜、水果、肉塊等。這些刀片通常具有特殊的格柵刃,以實現均勻的切割。

剝皮刀片: 用於去除水果、蔬菜或其他食材的外皮。這些刀片通常具有較平滑的刃邊,以確保剝皮時不損害食材。

魚刀片: 這些刀片專門用於處理魚類,包括去鱗、剖魚、切魚肉等工作。它們通常具有特殊的刃形狀,以適應魚類的形狀和結構。

擠壓刀片: 用於將食材擠壓成特定形狀,例如製作餅乾、麵麻花、餡餅等。

磨刀片: 這些刀片用於將食材磨成蓉狀或粉末,例如芝麻醬、香料等。

釀造刀片: 用於製作壽司、切割壽司或其他食物加工需要的特殊刀片。

食品加工刀片通常由不鏽鋼或其他耐腐蝕材料製成,以確保食品不受污染。此外,它們需要經常保持清潔和消毒,以確保食品加工過程中的安全性和衛生標準。選擇適合的刀片類型取決於食品加工工藝和所需的切割或處理方式。食品業常遵循嚴格的食品安全法規,以確保生產的食品是安全的。 食品加工刀片是用於食品機械的特殊刀具,通常具有特殊的設計和特點,以滿足食品加工工業的需求。這些刀片可以用於切割、切片、切丁、剝皮、擠壓、磨碎等多種不同的食品處理任務。以下是一些常見的食品加工刀片類型:

切片刀片:用於將肉類、蔬菜、奶製品等食品切成薄片或薄片狀。

切丁刀片:專門用於切成小丁狀的食材,如蔬菜、水果等。

剝皮刀片:用於去除水果或蔬菜的外皮。

擠壓刀片:用於將食材擠壓成特定形狀,如麵麻花或餅乾。

磨刀片:用於將食材磨成蓉狀或粉末,如芝麻醬或香料。

這些刀片通常由不鏽鋼或其他耐腐蝕材料製成,以確保它們不會對食品造成污染。刀片的設計和材料選擇通常考慮到食品安全和衛生要求,以確保生產的食品是安全的。

食品機械用刀片需要經常保持清潔和消毒,以確保食品加工過程中的安全性和衛生標準。此外,選擇適合的刀片類型取決於食品加工工藝和所需的切割或處理方式。台灣區的食品加工行業通常會使用各種不同類型的刀片,以滿足其特定需求。

刀片是一種薄而尖銳的刀具部件,通常用於切割、切割、割斷、刮除或刮取物體的表面。刀片可以具有各種形狀和尺寸,並根據特定的用途和工作需求而設計。

刀片通常由硬質材料製成,以確保其保持鋒利並能夠耐用。一些常見的刀片材料包括不鏽鋼、碳鋼、陶瓷、硬質合金等。不同的刀片材料具有不同的特性,因此選擇刀片材料取決於所需的切割或切割應用。

刀片的應用非常廣泛,包括:

工業切割:刀片在工業中用於切割金屬、塑料、紙張、布料等材料。

醫療手術:外科手術中使用的手術刀片用於切割組織。

建築和建造:刀片用於切割建築材料,如木材、石材和瓷磚。

廚房和食品處理:廚房刀片用於切割和處理食材,如切菜刀、切肉刀等。

美容和個人護理:刀片用於修剪頭髮、刮鬍子等美容和護理需求。

藝術和手工藝:藝術家和手工藝者使用刀片進行創作和製作。

農業和園藝:農業刀片用於割草、修剪樹木等農業和園藝工作。

刀片的設計可以因應不同的需求而有所不同,例如,刀片可以是單刃或雙刃的,有不同的刃形和邊緣角度,以適應不同的工作。

由於刀片通常非常鋒利,因此在使用時必須小心,遵守安全操作標準,以防止意外傷害。此外,定期保養和維護刀片是確保其效能和安全性的重要步驟。

不銹鋼刀片是一種常見的刀片材料,廣泛用於各種應用,包括食品加工、工業、醫療和家用刀具。以下是一些關於不銹鋼刀片的重要信息:

抗腐蝕性: 不銹鋼刀片以其出色的抗腐蝕性而聞名,這使其非常適合用於與水和食物接觸的應用。它們不易生鏽,可以長時間保持外觀和功能。

硬度: 不銹鋼刀片通常具有足夠的硬度,使其能夠保持刀刃的鋒利性,並有效地切割不同類型的材料,包括食材、塑料、紙張等。

刀刃保持: 不銹鋼刀片相對容易保持刀刃。然而,它們仍然需要定期維護和磨刀,以確保切割效能。

耐用性: 不銹鋼刀片具有較長的使用壽命,並且能夠在多種環境中適用。

食品處理: 由於其食品安全性和耐腐蝕性,不銹鋼刀片經常用於食品加工、廚房刀具和食品處理設備中,例如不銹鋼廚刀、不銹鋼切片機刀片等。

衛生標準: 不銹鋼刀片的表面通常光滑且容易清潔,這使其符合衛生標準,適用於食品業和醫療設施等需要高度衛生的環境。

多種應用: 不銹鋼刀片用於各種不同的應用,包括手工藝、建築、美容、醫療手術和更多領域。

需要注意的是,雖然不銹鋼刀片具有優越的特性,但它們仍然需要適當的保養和維護,包括定期磨刀和清潔,以確保其性能和壽命。不同型號的不銹鋼刀片可能有不同的特性和適用性,因此在選擇刀片時,應根據具體需求和應用來選擇適當的刀片類型。

不銹鋼刀片是一種常見的刀片材料,廣泛用於各種應用,包括食品加工、工業、醫療和家用刀具。以下是一些關於不銹鋼刀片的重要信息:

抗腐蝕性: 不銹鋼刀片以其出色的抗腐蝕性而聞名,這使其非常適合用於與水和食物接觸的應用。它們不易生鏽,可以長時間保持外觀和功能。

硬度: 不銹鋼刀片通常具有足夠的硬度,使其能夠保持刀刃的鋒利性,並有效地切割不同類型的材料,包括食材、塑料、紙張等。

刀刃保持: 不銹鋼刀片相對容易保持刀刃。然而,它們仍然需要定期維護和磨刀,以確保切割效能。

耐用性: 不銹鋼刀片具有較長的使用壽命,並且能夠在多種環境中適用。

食品處理: 由於其食品安全性和耐腐蝕性,不銹鋼刀片經常用於食品加工、廚房刀具和食品處理設備中,例如不銹鋼廚刀、不銹鋼切片機刀片等。

衛生標準: 不銹鋼刀片的表面通常光滑且容易清潔,這使其符合衛生標準,適用於食品業和醫療設施等需要高度衛生的環境。

多種應用: 不銹鋼刀片用於各種不同的應用,包括手工藝、建築、美容、醫療手術和更多領域。

需要注意的是,雖然不銹鋼刀片具有優越的特性,但它們仍然需要適當的保養和維護,包括定期磨刀和清潔,以確保其性能和壽命。不同型號的不銹鋼刀片可能有不同的特性和適用性,因此在選擇刀片時,應根據具體需求和應用來選擇適當的刀片類型。

刃形狀: 刀片的刃形狀通常取決於其用途。常見的刃形狀包括直刃、波浪刃、鋸齒刃、凹凸刃等。不同的刃形狀適用於不同的切割和切割需求。

刃邊角度: 刀片的刃邊角度是指刃口的夾角。刃邊角度的選擇可以影響刀片的切割效能和持久性。較小的刃邊角度通常使刀片更鋒利,但也更容易受損。

刀片固定方式: 刀片可以固定在不同的手柄或刀身上,具體取決於刀具的設計。有些刀片可以更換,這樣可以經常更換刀片以保持切割效能。

刀片安全性: 由於刀片非常鋒利,因此使用時必須格外小心。建議在使用刀片時戴上適當的安全手套,避免直接接觸刀片。

刀片磨損和維護: 刀片在使用過程中會磨損,因此需要定期檢查和維護。定期的磨刀可以保持刀片的鋒利度,並延長其使用壽命。

特殊用途刀片: 一些應用需要特殊設計的刀片,例如切割玻璃的刀片、切割骨頭的醫療刀片、切割紙張的圓盤刀片等。這些刀片在特定的工作中發揮重要作用。

法律和安全規定: 在使用刀片時,您應該遵守當地的法律法規和安全標準,以確保安全操作。

總之,刀片是各種應用中不可或缺的工具,但它們也需要謹慎使用和保養,以確保安全和效能。根據具體的需求和工作,選擇適當的刀片和刀具非常重要。

網狀刀片是一種特殊類型的刀片,通常用於食品加工機械中,用於切割、剝皮、切片或處理食品材料,尤其是用於切割蔬菜、水果和其他食材。以下是一些有關網狀刀片的重要信息:

切割原理: 網狀刀片的切割原理基於一個網格或網結構,其中有許多小刀刃或切割點,可以在通過食材時切割它們。這種設計可以實現均勻且快速的切割,尤其適用於處理大量的食材。

食品處理: 網狀刀片常用於切割蔬菜、水果、奶製品、面包等食材,以便製備食品,例如製作沙拉、切片薯條、切碎芝士等。

刀片設計: 網狀刀片的刀刃通常設計成鋒利的小刀或切割點,這些刀刃可以嵌套在一個網格結構中,以確保食材在通過刀片時能夠均勻地切割。

多功能性: 一些網狀刀片設計可調節切割大小,使其適用於不同的食材和切割需求。這種多功能性使其成為食品處理中的有用工具。

清潔和維護: 由於刀片常常用於食品處理,因此清潔和維護非常重要,以確保刀片保持衛生並避免食材殘留。一些網狀刀片可以容易拆卸和清潔。

食品安全: 網狀刀片通常由不銹鋼或其他食品安全材料製成,以確保食材不受污染。此外,它們應符合當地的食品安全法規。

網狀刀片是食品加工機械中常見的刀具類型,它們可以提高食品加工效率,並確保切割的均勻性。根據特定的食材和食品加工需求,可以選擇不同類型和大小的網狀刀片。 材質選擇: 刀片的材質是非常重要的,不同的材質適合不同的應用。例如,不鏽鋼刀片對於食品處理非常適用,因為它們不會生鏽。碳鋼刀片通常更鋒利,但需要更多的護理以防鏽蝕。

網狀刀片是一種特殊類型的刀片,通常用於食品加工機械中,用於切割、剝皮、切片或處理食品材料,尤其是用於切割蔬菜、水果和其他食材。以下是一些有關網狀刀片的重要信息:

切割原理: 網狀刀片的切割原理基於一個網格或網結構,其中有許多小刀刃或切割點,可以在通過食材時切割它們。這種設計可以實現均勻且快速的切割,尤其適用於處理大量的食材。

食品處理: 網狀刀片常用於切割蔬菜、水果、奶製品、面包等食材,以便製備食品,例如製作沙拉、切片薯條、切碎芝士等。

刀片設計: 網狀刀片的刀刃通常設計成鋒利的小刀或切割點,這些刀刃可以嵌套在一個網格結構中,以確保食材在通過刀片時能夠均勻地切割。

多功能性: 一些網狀刀片設計可調節切割大小,使其適用於不同的食材和切割需求。這種多功能性使其成為食品處理中的有用工具。

清潔和維護: 由於刀片常常用於食品處理,因此清潔和維護非常重要,以確保刀片保持衛生並避免食材殘留。一些網狀刀片可以容易拆卸和清潔。

食品安全: 網狀刀片通常由不銹鋼或其他食品安全材料製成,以確保食材不受污染。此外,它們應符合當地的食品安全法規。

網狀刀片是食品加工機械中常見的刀具類型,它們可以提高食品加工效率,並確保切割的均勻性。根據特定的食材和食品加工需求,可以選擇不同類型和大小的網狀刀片。 材質選擇: 刀片的材質是非常重要的,不同的材質適合不同的應用。例如,不鏽鋼刀片對於食品處理非常適用,因為它們不會生鏽。碳鋼刀片通常更鋒利,但需要更多的護理以防鏽蝕。

保持鋒利: 鋒利的刀片更安全並且更容易使用,因此應定期磨刀或研磨以保持其鋒利度。使用磨刀石或刀具研磨器可以實現這一目標。

刀具收納: 刀片應存放在安全且適當的位置,以避免損壞刀片或造成意外傷害。使用刀架、磁性刀架或刀具保護套來儲存刀片。

專業維護: 對於需要高度精密的刀片,例如手術刀片,應當交由專業人員進行維護和消毒,以確保安全和衛生。

刀片的應用技巧: 學習正確的刀片使用技巧非常重要,這包括切割的手勢、角度、壓力等。使用正確的技巧可以提高效能並降低受傷的風險。

個人防護: 在使用刀片時,請始終戴上適當的個人防護裝備,包括安全手套和護目鏡,以減少潛在傷害的風險。

處理廢棄刀片: 使用後的刀片應該妥善處理。一些刀片具有專用的安全儲存和處理方法,以確保安全地丟棄它們。

刀片的保固和質保: 當購買刀片時,了解其保固和質保條件非常重要。這有助於確保在刀片損壞或存在缺陷時可以獲得適當的支持。

總之,刀片和刀具在許多不同的應用中都扮演著關鍵角色。了解刀片的選擇、使用和維護原則對於安全和效能都至關重要。根據具體的應用和需求,您可以選擇適合的刀片類型和刀具,並遵守相關的安全標準和建議。

blade

A blade refers to a thin-shaped cutting tool used for cutting, removing or trimming materials. A blade refers to a thin-shaped cutting tool used for cutting, removing or trimming materials. It is usually made of metal materials, such as stainless steel, high carbon steel, and tungsten carbide. wait. The shape and size of the blade can be designed and manufactured according to different application requirements, such as straight knives, curved knives, curved knives, serrated knives, etc.

Blades are commonly used in a variety of cutting and processing jobs such as food processing, textiles, medical devices, manufacturing, etc. Different applications require different types of blades. For example, food processing requires the use of stainless steel blades to avoid the production of harmful substances, and the textile industry requires the use of tungsten carbide blades.

The following points need to be noted when selecting and using blades:

Appropriate blade material: Different applications require blades of different materials, which need to be selected according to the specific situation.

Correct blade size and shape: The size and shape of the blade need to be designed and selected based on the characteristics and requirements of the material being cut.

Safe use: You need to pay attention to safety when using blades to avoid injuries caused by sharp blades.

Regular maintenance and replacement: Blades need to be maintained and replaced regularly to ensure their good use and effectiveness.

Overall, a blade is a very practical and important cutting tool that can be used in a variety of different industrial fields. You need to pay attention to safety and maintenance when using the blade to ensure its good use effect and service life.

Special purpose blades are blades designed for use in a specific industry or application. These blades usually need to be designed and manufactured according to different applications to adapt to different cutting and processing requirements.

Here are some common special purpose blades:

Medical device blades: used in medical fields such as surgery, cuts and sutures, which require extremely high precision and sharpness.

Electronic Parts Blades: Used for cutting, trimming and machining tiny electronic parts that require very high precision and flexibility.

Plastic blades: used for cutting, processing and trimming various plastic products. Suitable materials and designs need to be selected.

Paper blade: used in paper processing, printing and other processes, which require good cutting effect and stability.

Food blades: For food processing and handling, non-toxic, stainless steel and other materials need to be used to ensure food safety and hygiene.

The design and manufacture of special-purpose blades requires a professional design team and production technology to ensure that they meet application requirements and standards. When using special-purpose blades, you need to pay attention to safety and maintenance, and perform regular maintenance and replacement to ensure good use and service life.

Overall, special purpose blades are indispensable cutting tools in various industries and applications and can be applied to a variety of different cutting and processing requirements. According to different applications and requirements, suitable special-purpose blades need to be selected to ensure work efficiency and quality.

Food processing blades are blades specifically designed for food handling and processing. These blades have special features and designs to ensure food safety and hygiene and are able to handle a variety of different types of ingredients efficiently. Here are some common food processing blade types and features:

Slicing blades: These blades are usually used to cut meat, vegetables, dairy products and other ingredients into thin slices or flakes, such as slicing raw meat, cutting potato chips, etc.

Ding blade: Specially used to cut ingredients into small dices, such as vegetables, fruits, meat, etc. These blades often have special grating edges to achieve an even cut.

Peeling blade: Used to remove the skin from fruits, vegetables or other ingredients. These blades usually have a smoother edge to ensure that the food is not damaged when peeling.

Fish blades: These blades are specially designed for handling fish, including descaling, filleting, and carving. They often have a special blade shape to fit the shape and structure of the fish.

Extrusion blade: Used to squeeze ingredients into specific shapes, such as making biscuits, dough twists, pies, etc.

Grinding blades: These blades are used to grind ingredients into puree or powder, such as tahini, spices, etc.

Brewing Blade: Special blade used for making sushi, cutting sushi, or other food processing needs.

Food processing blades are usually made of stainless steel or other corrosion-resistant materials to ensure that food is not contaminated. In addition, they need to be kept clean and disinfected frequently to ensure safety and hygiene standards during food processing. Choosing the right blade type depends on the food processing process and the type of cutting or processing required. The food industry often follows strict food safety regulations to ensure that the food produced is safe. Food processing blades are specialized knives used in food machinery, often with special designs and features to meet the needs of the food processing industry. These blades can be used for cutting, slicing, dicing, peeling, squeezing, grating and many different food handling tasks. Here are some common food processing blade types:

Slicing blade: used to cut meat, vegetables, dairy products and other foods into thin slices or flakes.

Ding blade: specially used to cut ingredients into small dices, such as vegetables, fruits, etc.

Peeling Blade: Used to remove the outer skin of fruits or vegetables.

Extrusion blade: Used to squeeze ingredients into specific shapes, such as dough twists or biscuits.

Grinding blade: used to grind ingredients into paste or powder, such as sesame paste or spices.

These blades are usually made of stainless steel or other corrosion-resistant materials to ensure they do not contaminate food. The design and material selection of the blades usually take into account food safety and hygiene requirements to ensure that the food produced is safe.

Blades used in food machinery need to be kept clean and disinfected frequently to ensure safety and hygiene standards during food processing. Additionally, choosing the right blade type depends on the food processing process and the type of cutting or processing required. The food processing industry in Taiwan often uses a variety of different types of blades to meet their specific needs.

A blade is a thin, sharp knife component typically used to cut, cut, sever, scrape, or scrape the surface of an object. Blades can come in a variety of shapes and sizes and are designed for specific uses and job requirements.

Blades are usually made of hard materials to ensure they stay sharp and last a long time. Some common blade materials include stainless steel, carbon steel, ceramic, carbide, etc. Different blade materials have different properties, so the choice of blade material depends on the desired cutting or cutting application.

Blades are used in a wide range of applications including:

Industrial Cutting: Blades are used in industry to cut metal, plastic, paper, cloth and other materials.

Medical Surgery: A scalpel blade used in surgery is used to cut tissue.

Building and Construction: Blades are used to cut building materials such as wood, stone, and tile.

Kitchen and Food Handling: Kitchen blades are used for cutting and handling ingredients, such as kitchen knives, meat cleavers, etc.

Beauty and Personal Care: Blades are used for hair trimming, shaving and other beauty and care needs.

Arts and Crafts: Artists and crafters use blades to create and craft.

Agriculture and Gardening: Agricultural blades are used for agricultural and gardening tasks such as mowing grass and trimming trees.

The design of the blade can vary according to different needs. For example, the blade can be single-edged or double-edged, with different edge shapes and edge angles to suit different tasks.

Because blades are often very sharp, care must be taken when using them and safe handling standards are followed to prevent accidental injury. Additionally, regular care and maintenance of your blades is an important step in ensuring their effectiveness and safety.

Stainless steel blades are a common blade material used in a variety of applications, including food processing, industrial, medical, and household knives. Here is some important information about stainless steel blades:

Corrosion Resistance: Stainless steel blades are known for their excellent corrosion resistance, which makes them ideal for use in applications that come in contact with water and food. They are not prone to rust and will maintain their appearance and functionality for a long time.

Hardness: Stainless steel blades are generally hard enough to allow them to maintain their edge sharpness and effectively cut through different types of materials, including food, plastic, paper, and more.

Edge retention: Stainless steel blades maintain their edge relatively easily. However, they still require regular maintenance and sharpening to ensure cutting performance.

Durability: Stainless steel blades have a long service life and can be used in a variety of environments.

Food Processing: Due to its food safety and corrosion resistance, stainless steel blades are often used in food processing, kitchen knives and food processing equipment, such as stainless steel kitchen knives, stainless steel slicer blades, etc.

Hygiene Standards: The surface of stainless steel blades is generally smooth and easy to clean, making them compliant with hygiene standards and suitable for environments that require a high degree of hygiene, such as the food industry and medical facilities.

Multiple Applications: Stainless steel blades are used in a variety of different applications including crafts, construction, cosmetology, medical procedures and many more.

It's important to note that while stainless steel blades have superior properties, they still require proper care and maintenance, including regular sharpening and cleaning, to ensure their performance and longevity. Different models of stainless steel blades may have different characteristics and suitability, so when selecting a blade, the appropriate blade type should be selected based on specific needs and applications.

Edge Shape: The edge shape of a blade usually depends on its use. Common blade shapes include straight blades, wavy blades, serrated blades, concave-convex blades, etc. Different blade shapes are suitable for different cutting and cutting needs.

Edge angle: The edge angle of the blade refers to the angle between the cutting edges. The choice of edge angle can affect the cutting performance and durability of the blade. A smaller edge angle generally makes the blade sharper, but also more susceptible to damage.

Blade attachment: The blade can be attached to different handles or bodies, depending on the design of the knife. Some blades are replaceable, so the blades can be replaced frequently to maintain cutting performance.

Blade Safety: Since the blades are very sharp, extreme care must be taken when using them. It is recommended to wear appropriate safety gloves when using the blade and avoid direct contact with the blade.

Blade wear and maintenance: Blades wear out with use and require regular inspection and maintenance. Regular sharpening will keep your blade sharp and extend its life.

Special purpose blades: Some applications require specially designed blades, such as blades for cutting glass, medical blades for cutting bones, disc blades for cutting paper, etc. These blades play an important role in specific jobs.

Legal and Safety Regulations: When using the blade, you should comply with local laws, regulations and safety standards to ensure safe operation.

In summary, blades are essential tools in a variety of applications, but they also require careful use and care to ensure safety and effectiveness. Depending on the specific needs and job, it is important to choose the appropriate blades and knives.

A mesh blade is a special type of blade commonly used in food processing machinery for cutting, peeling, slicing or handling food materials, especially for cutting vegetables, fruits and other ingredients. Here is some important information about mesh blades:

Cutting Principle: The cutting principle of the mesh blade is based on a grid or mesh structure with many small blades or cutting points that cut the ingredients as they pass through them. This design allows for even and fast cutting, especially when handling large quantities of ingredients.

Food processing: Mesh blades are often used to cut vegetables, fruits, dairy products, bread and other ingredients for food preparation, such as making salads, slicing French fries, shredding cheese, etc.

Blade design: The edges of mesh blades are typically designed as sharp knives or cutting points, and these edges can be nested in a grid structure to ensure ingredients are cut evenly as they pass through the blade.

Versatility: Some mesh blade designs allow for adjustable cut size, making them suitable for different ingredients and cutting needs. This versatility makes it a useful tool in food handling.

Cleaning and Maintenance: Since blades are often used for food handling, cleaning and maintenance are important to ensure they remain sanitary and avoid food residue. Some mesh blades can be easily removed and cleaned.

Food Safety: Mesh blades are usually made of stainless steel or other food-safe materials to ensure ingredients are not contaminated. Additionally, they should comply with local food safety regulations.

Mesh blades are a common type of knife found in food processing machinery. They improve food processing efficiency and ensure uniformity of cuts. Different types and sizes of mesh blades are available depending on specific ingredients and food processing needs. Material selection: The material of the blade is very important, and different materials are suitable for different applications. For example, stainless steel blades are great for food handling because they don't rust. Carbon steel blades are generally sharper but require more care to prevent rust.

Keep it sharp: Sharp blades are safer and easier to use, so they should be sharpened or ground regularly to maintain their sharpness. This can be accomplished using a whetstone or knife grinder.

Knife Storage: Blades should be stored in a safe and appropriate location to avoid damage to the blade or accidental injury. Use a knife holder, magnetic knife holder or knife protector to store your blades.

Professional maintenance: Blades that require high precision, such as surgical blades, should be maintained and sterilized by professionals to ensure safety and hygiene.

Blade Application Techniques: It is important to learn correct blade usage techniques, including cutting gestures, angles, pressure, etc. Using the right technique can improve performance and reduce the risk of injury.

Personal Protection: When working with blades, always wear appropriate personal protective equipment, including safety gloves and goggles, to reduce the risk of potential injury.

Disposal of discarded blades: Blades should be disposed of properly after use. Some blades have dedicated safe storage and handling methods to ensure they are discarded safely.

Blade Warranty and Warranty: When purchasing a blade, it is important to understand its warranty and warranty conditions. This helps ensure proper support is available if the blade is damaged or defective.

In conclusion, blades and knives play a key role in many different applications. Understanding the principles of blade selection, use and maintenance is critical to safety and performance. Depending on your specific application and needs, you can choose the right blade type and tool and adhere to relevant safety standards and recommendations.