Specialized blade design

Specialized blade design

Specialized blade design

Specialized Blade Design: Crafting Precision Solutions for Unique Challenges

Introduction: Specialized blade design represents the pinnacle of engineering innovation, where precision meets purpose to address unique challenges across diverse industries. In this extensive exploration, we delve into the intricate world of specialized blade design, uncovering the creative processes, advanced technologies, and real-world applications that define this dynamic field.

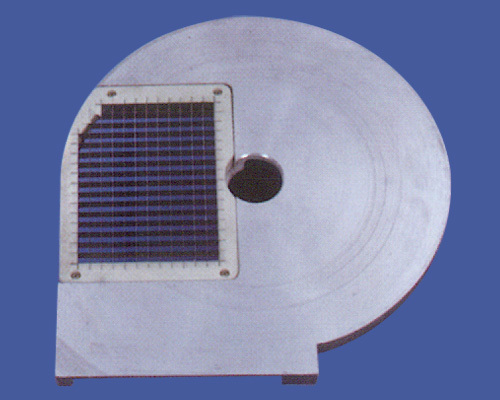

Section 1: Understanding Specialized Blade Design Specialized blade design goes beyond conventional blade manufacturing, focusing on tailoring solutions to meet specific application requirements. It involves a deep understanding of cutting dynamics, material properties, and environmental factors. From high-speed cutting to intricate surgical procedures, specialized blades are designed to excel in demanding and specialized tasks.

Section 2: The Artistry of Design At the heart of specialized blade design lies the artistry of design, where engineers and designers collaborate to conceptualize and create precision-engineered solutions. This phase involves meticulous attention to detail, with a focus on optimizing blade geometry, edge sharpness, and cutting efficiency. CAD software and simulation tools enable designers to explore design iterations and refine concepts before production.

Section 3: Materials Selection and Optimization Materials selection is critical in specialized blade design, with a wide range of alloys, ceramics, and composites available to meet specific performance requirements. Each material offers unique properties such as hardness, wear resistance, and thermal stability, which are carefully evaluated and optimized for the intended application. Advanced manufacturing techniques such as powder metallurgy and chemical vapor deposition enable the production of high-performance blade materials with exceptional precision and consistency.

Section 4: Tailoring Blades for Unique Applications Specialized blades find applications across a diverse range of industries, each with its own set of challenges and requirements. In aerospace, specialized blades are designed for precision machining of advanced materials such as carbon fiber-reinforced composites. In the medical field, specialized surgical blades are engineered for precise incisions and minimal tissue trauma. From automotive manufacturing to electronics fabrication, specialized blades play a critical role in enhancing efficiency, quality, and safety.

Section 5: Precision Engineering in Practice Precision engineering lies at the core of specialized blade design, with manufacturers employing advanced metrology tools and quality control processes to ensure the highest level of accuracy and performance. Dimensional tolerances, surface finish, and cutting edge geometry are meticulously scrutinized to meet stringent specifications and deliver consistent results. From initial prototyping to final production, every step of the manufacturing process is optimized for precision and reliability.

Section 6: Innovations Driving Specialized Blade Design The field of specialized blade design is continuously evolving, driven by innovations in materials science, manufacturing technologies, and design optimization. Additive manufacturing techniques such as 3D printing enable the production of complex blade geometries with unparalleled precision and efficiency. Computational modeling and simulation tools allow designers to explore new design concepts and optimize performance parameters with unprecedented accuracy. These innovations are reshaping the landscape of specialized blade design, opening new possibilities for efficiency, versatility, and performance across a wide range of applications.

Section 7: Sustainability and Environmental Responsibility In an era of increasing environmental awareness, sustainability and environmental responsibility are becoming key considerations in specialized blade design. Manufacturers are embracing sustainable materials, recycling initiatives, and energy-efficient manufacturing processes to minimize environmental impact and promote long-term sustainability. From eco-friendly blade coatings to recyclable packaging solutions, the industry is taking proactive steps to reduce its carbon footprint and preserve natural resources for future generations.

Section 8: Global Market Dynamics The global market for specialized blade design is characterized by robust growth, driven by increasing demand from key end-user industries such as aerospace, medical devices, and precision engineering. Market players are expanding their product portfolios and geographic footprint to capitalize on emerging opportunities in regions such as Asia-Pacific, Latin America, and the Middle East. Strategic partnerships, mergers, and acquisitions are reshaping the competitive landscape, as companies seek to strengthen their market position and gain a competitive edge in an increasingly globalized marketplace.

Section 9: Conclusion and Outlook In conclusion, specialized blade design represents the pinnacle of engineering innovation, offering precision-engineered solutions to meet the unique challenges of modern industry. As we look ahead, the future of specialized blade design is bright, fueled by a relentless pursuit of excellence and a commitment to pushing the boundaries of what is possible. Let us continue to embrace innovation, collaboration, and sustainability as we strive to create a future where specialized blades play a central role in driving efficiency, quality, and progress across a wide range of industries.